VR microdisplay module: screen determines core parameters, upgrades from Fast-LCD to silicon-based OLED

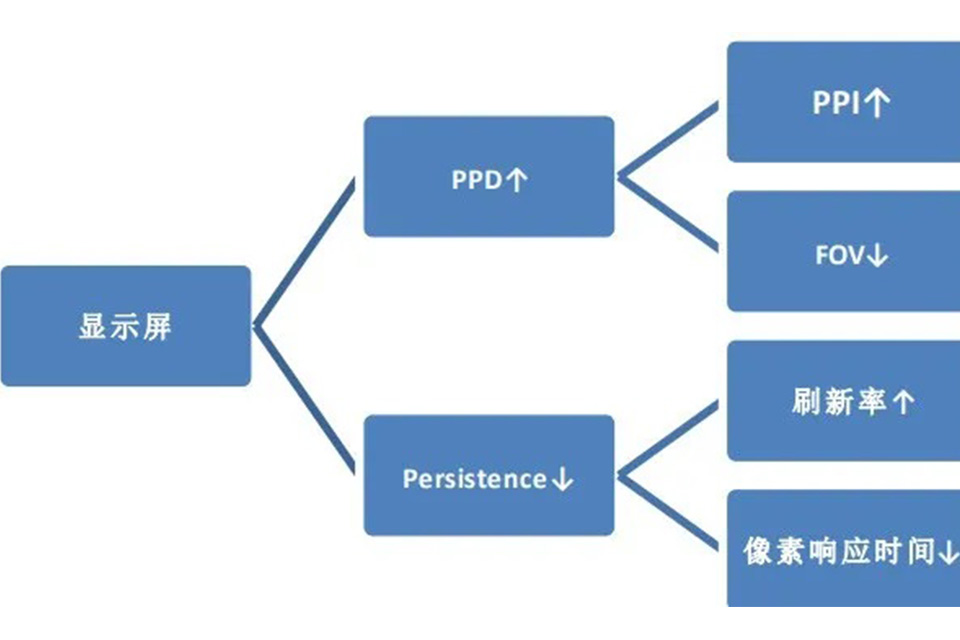

The core screen parameters of microdisplay modules, PPD and Persistence, determine clarity and dizziness, and the display screen continues to upgrade to improve user experience.

PPD (Pixel Per Degree; PPD=PX/FOV) determines clarity: Unlike traditional screens, near-eye devices such as VR use angular resolution PPD to measure screen clarity, which refers to the field of view angle, which represents the number of pixels filled in an average of 1° angle.

Because VR screens are close to the eyes, the PPI (Pixels Per Inch; PPI=√length pixels 2 + width pixels 2 screen size) pixel density indicator is introduced.

Due to the special split-screen playback format of VR, a single picture will only use half of the screen's pixels when displayed. In addition, due to the influence of factors such as optical lenses and screen materials, the complex optical system between the user's eyes and the display panel will seriously reduce the image quality, and the VR perception resolution is far lower than the panel resolution.

The equivalent VR screen resolution of a single eye is closest to the 16K resolution (15360 x 8640, 132 million pixels). Currently, the Oculus Quest 2 display can provide a single-eye resolution of 1832 x 1920 pixels, and iQiyi Qiyu 2pro can achieve a single-eye 4K resolution, which is still far from the human retinal resolution. Improving PPD can be achieved by 1) increasing PPI and 2) reducing FOV, but increasing PPI further increases the requirements for the screen, and reducing FOV will affect immersion.

Persistence determines the degree of dizziness:

The afterglow effect refers to the fact that when the human eye observes the scene, the light signal is transmitted to the human brain nerves for a short period of time. After the light effect ends, the visual image does not disappear immediately, resulting in dizziness. In order to reduce the dizziness, VR devices need a high refresh rate to reduce the screen afterglow.

To weaken the afterglow phenomenon, VR devices can 1) increase the refresh rate or 2) reduce the pixel response time. If the refresh rate can reach 200hz, the dizziness will be greatly reduced.

Among them, increasing the refresh rate will increase system power consumption, and reducing the pixel response time will pose greater challenges to driving technology and pixel materials.

The screen is one of the most important factors in determining the immersive experience, and it has high requirements for resolution/PPI and refresh rate.

High pixel arrangement density PPI can solve the screen door effect. The screen door effect refers to the dancing of fine lines and the separated flickering of high-contrast edges caused by real-time rendering when there are insufficient pixels.

The screen door effect is mainly caused by insufficient sub-pixel arrangement density. The larger the spacing between sub-pixels, the more obvious the non-luminous part. Through VR, it looks like a screen window in front of your eyes, which has a blurry feeling and affects the immersion and visual clarity of VR. High refresh rate makes the picture smoother, reduces picture delay and ghosting, and relieves dizziness.

Generally speaking, VR devices need to have a refresh rate of at least 120Hz and a resolution of 4K or above to avoid dizziness. Latency is the reciprocal of refresh rate. The latency corresponding to a refresh rate of 120Hz is 8.33ms. The human eye can clearly perceive the increase from 90-120Hz to 160-180Hz. After exceeding 250Hz, the sensitivity of the human eye to the increase in refresh rate will gradually decrease.

Currently, the mainstream screen is mainly Fast-LCD, which takes into account high refresh rate and cost performance. Generally, the refresh rate of OLED screens is obviously superior, but the screen door effect is more obvious and the cost is higher. The sub-pixel pitch of LCD screens is smaller than that of OLED, and the screen door effect is much reduced. The improved Fast-LCD technology uses new liquid crystal materials (ferroelectric liquid crystal materials) and overdrive technology to effectively increase the refresh rate to 75-90Hz. It also has high mass production stability and yield, and has both effect and cost performance.

In 2018, BOE's VR-specific display module shipments reached 1 million pieces, involving more than 20 VR complete products, including Oculus Quest 2 and Huawei VR.

Oculus Quest 2 uses a modified Fast-LCD to replace the two AMOLEDs in the previous generation Quest product.

Silicon-based OLED, the mainstream screen in the future, will be the best solution.

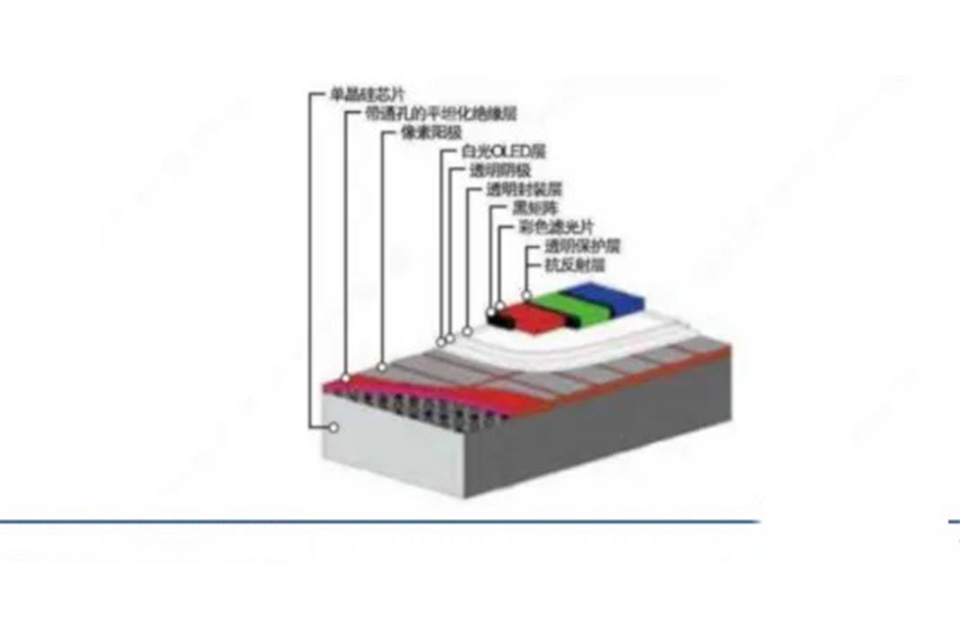

The backplane of AMOLED devices generally uses amorphous silicon, microcrystalline silicon or low-temperature polycrystalline silicon thin-film transistors, while silicon-based OLED innovatively combines semiconductors and OLEDs, and the display device uses a single-crystal silicon chip substrate.

The single-crystal silicon chip uses the existing mature integrated circuit CMOS process to realize the active addressing matrix of the display screen pixels while realizing the driving control circuit with multiple functions such as SRAM memory and T-CON, which greatly reduces the external connection of the device, increases reliability, and achieves lightweight.

In addition, the pixel size of the silicon-based OLED micro-display device is 1/10 of that of the traditional display device, and the fineness is much higher than that of the traditional device.

The superior performance of silicon-based OLED includes:

1) Ultra-high resolution:

The resolution PPD of VR equipment is pulled to the upper limit of the human eye resolution, which enhances the immersive experience. The human eye has a normal visual acuity with a limit angular resolution of about 50-60 PPD, while the existing single-screen 4K (resolution of 3840×2160) VR headset with a field of view of 120° is about 18 PPD; the single-screen 2K (resolution of 1920×1080) VR headset with a field of view of 60° is about 36.7 PPD. The resolution of silicon-based OLED 2000 PPI is significantly higher than the 800 PPI of traditional low-temperature polysilicon LTPS-OLED displays, thereby increasing the PPD of VR devices to 60 PPD.

2) Ultra-high refresh rate:

The refresh rate can reach 2000 Hz, which effectively reduces the dizziness of VR devices. Low refresh rate leads to stronger image flicker and jitter, which eventually causes symptoms such as eye pain and dizziness, which is an important reason for dizziness when using VR devices. A refresh rate of 120Hz can improve the image jump and blur of motion shots, and completely eliminate the critical flicker phenomenon under high brightness and wide viewing angle. The refresh rate of silicon-based OLED can reach 2000Hz, which greatly exceeds the maximum refresh rate of 90Hz of existing VR devices.

3) Small size and light weight, greatly improving the user experience:

The pixels of silicon-based OLED micro-display devices are only 1/10 of those of traditional display devices. In addition, silicon-based OLED uses single-crystal silicon chips as the substrate, which reduces the external connections of the device and reduces the weight by more than 50% compared with other display solutions.

AR: LCOS is the current main AR solution, and MicroLED is the best in the long term

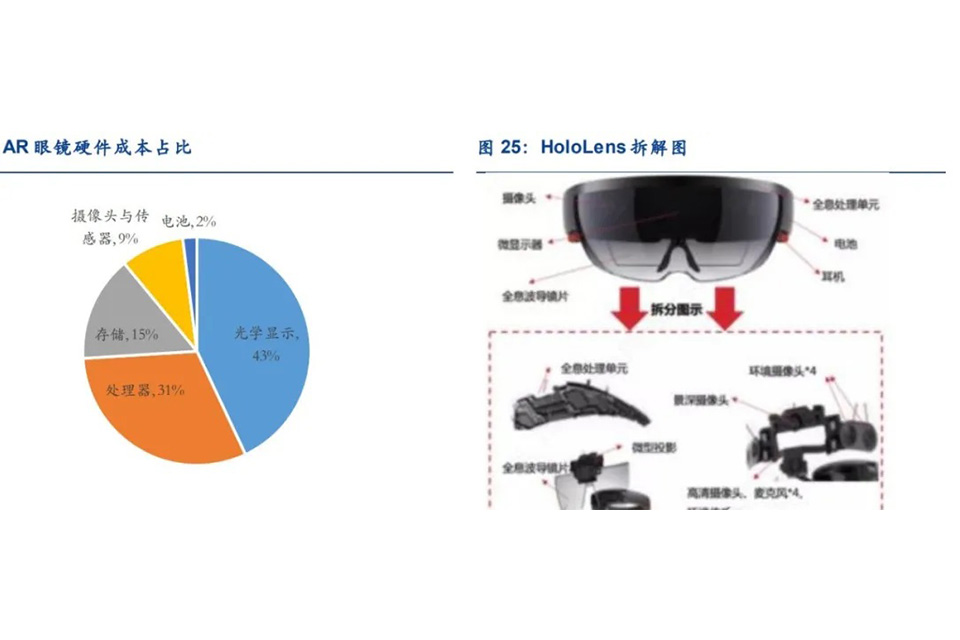

The field of optics and display is still an important breakthrough point for AR hardware, and optics and display account for 43% of the cost of $1,000 AR hardware. The optics and display modules of AR glasses include near-eye display (i.e. optical lenses), micro-displays, and depth of field technologies related to the two.

Optical display is the core component of AR glasses, which affects the final imaging effect. Optical display is to AR glasses what screen is to mobile phones. The rest of the supply chain of AR glasses overlaps with smartphones to a high degree, and the barriers to mass production and popularization are low.

Taking HoloLens as an example, the main hardware includes holographic processing module, 2 light-guide transparent holographic lenses, 2 LCos micro-projectors and 6 cameras, with a total cost of US$1,500. Among them, the LCos micro-projection device and transparent holographic lens cost US$570 (the cost of a single LCos micro-projector from some Chinese manufacturers ranges from 500 to 1,000 yuan), accounting for 43%, the holographic processing unit (CPU, GPU, HPU) costs about US$400, accounting for 31%, the storage device costs US$200, the 6 cameras and sensors cost US$100, and the battery costs US$30.

LCOS is the main solution for AR micro-display at present, and MicroLED is the best solution in the long run. AR has four types of display solutions: LCOS, DLP, silicon-based OLED, and MicroLED, among which LCOS is the main solution at present, and waveguide + MicroLED is the best solution in the long run.

LCOS (liquid crystal on silicon) fills the liquid crystal molecules between the upper glass substrate and the lower metal reflective layer. The voltage between the metal reflective layer and the top ITO common electrode jointly determines the light transmittance of the liquid crystal molecules, and the display drive circuit is directly prepared on the silicon substrate.

The display principle of LCoS is that the incident S-polarized light passes through the liquid crystal layer. If the liquid crystal does not produce twisting, it will still be S-polarized light when it reaches the bottom metal reflective layer and reflects back, and it will pass through the liquid crystal layer and emit.

Then it is reflected back to the original light path through the PBS prism, and the light does not enter the projection light path, that is, this pixel is in a "dark state".

On the contrary, if the liquid crystal is deflected, the incident S-polarized light will be polarized when passing through the liquid crystal layer, and can pass through the PBS prism and enter the projection light path, that is, it will appear "bright state".

The production process of LCoS is mainly to prepare the liquid crystal layer and various protective reflective layers to the silicon-based drive through etching and deposition through semiconductor processes.

At present, due to the maturity of LCOS mass production process, most parameters are adapted to optical waveguides, which is currently the main solution for AR. DLP digital light processing (Digital Light Processing), the principle is similar to LCoS, but it does not process optics through liquid crystal, but through prisms. The core of DLP lies in DMD (Digital Micromirror Device), and this core MEMS device has been monopolized by TI for a long time. The production process is mainly to use semiconductor processes to make MEMS systems to control the deflection of prisms, thereby controlling the light path.

The principle of the silicon-based OLED (OLED-on-Silicon) solution is similar to that of the traditional OLED solution. Since it is difficult to drive small-sized pixels on a glass substrate, the CMOS process is used instead. However, due to the low brightness of the OLED solution, it is not effective when used outdoors with an optical waveguide. The silicon-based OLED solution will limit the use scenarios of AR, and the effect is not good when used with an optical waveguide. It is not a mainstream solution at present.

Micro-LED highly integrated semiconductor information display technology refers to a display technology that uses self-luminous micron-level LEDs as light-emitting pixel units and assembles them on a driving panel to form a high-density LED array. Due to the small size, high integration and self-luminescence of micro LED chips, it has greater advantages in brightness, resolution, contrast, energy consumption, service life, response speed and thermal stability compared with LCD and OLED in terms of display.

Micro-LED is currently recognized as the best solution in the industry. Its refresh rate, brightness, light-emitting mode, pixel density and other indicators can provide the best performance indicators. However, due to its pixel size and pitch of several microns, it poses a great challenge to mass production and full-color solutions.

JBD has achieved mass production of monochrome Micro LED wafers with a dot pitch of 5μm and 5000DPI in 2020; as Heitz's law drives LED costs to continue to drop, chip size continues to decrease, and Micro LED is rapidly landing, and is expected to become the final AR display technology with optical waveguide.

The significant advantages of Micro-LED are built on complex process flows and strict technical thresholds. Micro-LED display mainly includes process flows such as epitaxial growth, drive backplane production, chip production, and batch transfer. Among them, chip manufacturing, mass transfer, and driving are the main pain points of Micro-LED industrialization, and mass transfer is even more "difficult".

At present, the industry has introduced transfer technologies such as Stamp transfer, laser transfer, self-assembly transfer, bonding, and Interpose, but overall, the maturity and yield level of transfer technology still need to be improved, requiring continuous exploration and optimization of the entire industry chain.

Contact: Ashley Wu

Phone: +86 17773983073

E-mail: [email protected]

Add: 708 Room A Buiding Huafeng International Robot Industrial Park Xixiang Bao'an